Since our company was founded we are developing custom-made solutions and products made of PTFE and modified PTFE for applications in the laboratory sector. Examples are digestion vessels for sample preparation and trace analysis or Inliner for high-pressure reactors in research and development. Modified PTFE, also known under the name 3MTMDyneonTMTFMTM, has an extremely anti-adhesive surface, a low microporosity and a high hydrophobicity. This prevents cross-contamination and makes cleaning easy. The isostatic molding is the basic requirement in order to be able to produce vessels without a support sleeve. And it guarantees high stability, material purity and quality. Vessels manufactured by this process withstand pressures up to 40 bar. And they are distinguished by a remarkably long lifespan, which exceeds that of other materials considerably.

Advantages

Wide temperature range of –200 to +260 °C for high temperature digestions

Universal chemical resistance, even against aggressive acids such as aqua regia

Highly hydrophobic with slightest permeation behaviour

Extremely anti-adhesive for residue-free cleaning

Low refractive index of ~1,38

Physiologically harmless

Outstanding mechanical processing features

Reaction Vessels

Reaction vessels and linings made of virginal or modified PTFE are particularly suitable for metal-free working with highly corrosive media under pressure and temperature. Our comprehensive range of vessel volumes allows specific configurations and an extraordinary productivity.

The PTFE reactor linings are several millimeters thick and provide effective protection of the media-wetted parts against corrosive media like acids or bases. Furthermore, the PTFE inserts effectively minimize the risk of cross-contamination and catalyst poisoning and can also be used as funtional storage vessels for reaction solutions.

Digestion Vessels

A specific core competence of Berghof Fluoroplastics is the production of pressure digestion vessels. The isostatic molding is the basic requirement in order to be able to produce vessels made from highly pure, modified PTFE. Pressure vessels from Berghof Fluoroplastics provide users with maximum safety, because they withstand self-supporting pressures up to 40 bar and are highly temperature resistant.

Advantages

Solid and durable pressure vessels made of virginal or modified PTFE

Secure clasp system even at high pressures

Digestion vessels could be used with the mineral acids HCl, HNO3, HF, H2SO4 and H3PO4

Non-contact, optical capture of the sample temperatures is in all vessels in real time possible

Digestion vessels for small sample volumes < 6 ml available upon request

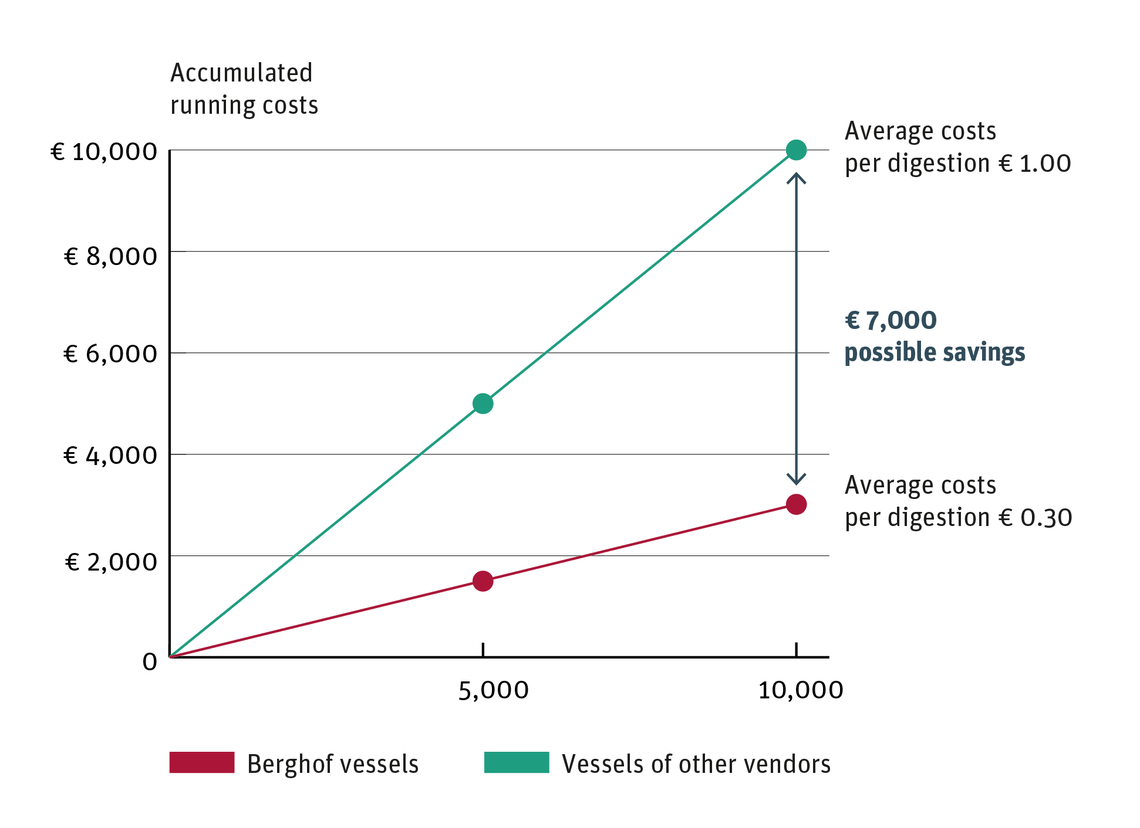

Due to the quality processing and the long lifespan of our PTFE vessels the running costs per digestion are remarkably reduced at the microwave systems of our sister company Berghof Products+Instruments. The cost will be € 0.30 for Berghof vessels, while the vessels of other suppliers will cause average costs of € 1.00 per digestion. Therefore you can reduce the running costs about approximately € 7,000 if you make 10,000 digestions.

![[Translate to English:] Branche Labortechnik [Translate to English:] Branche Labortechnik](/fileadmin/_processed_/a/1/csm_BFT_Labortechnik_kachel_71e3ad3503.jpg)

![[Translate to English:] Nassprozess-Equipment aus High Density PTFE [Translate to English:] Nassprozess-Equipment aus High Density PTFE](/fileadmin/_processed_/2/1/csm_NassprozessEquipment_Kachel_2_01_9ff9cbcab9.jpg)

![[Translate to English:] Werkstoffe [Translate to English:] Werkstoffe](/fileadmin/_processed_/7/d/csm_BFT_Werkstoff_kachel_u_c78e21dabb.png)