Photonics, the science and technology of light, is one of the most important growth and future industries - and this positive trend will even intensify in the coming years. No wonder that the European Commission identified photonics as one of the five "key enabling technologies" for the successful future of Europe in 2009 already - and is promoting it accordingly. After about 20 years of experience with photonic issues, we can say that there is no way around Optopolymer® and its diffuse reflection properties. This is why our components and optical materials are increasingly in demand in numerous industries around the globe and are proving their worth again and again in a wide range of applications.

The first choice for many photonic applications: Optical materials and coatings from Berghof

Together with its customers Berghof has been developing products and material solutions made of the high-performance plastic Polytetrafluoroethylene (PTFE) for more than 50 years. This makes us one of the absolute pioneers in this field. We have also been involved in photonics for some time now. More than 20 years ago, we started to develop material solutions based on our PTFE especially optimized for use in optical applications. After many years of experience in numerous fields of application we know: Due to its unique surface structure, Optopolymer® from Berghof has ideal properties for various applications in the field of photonics and especially optical metrology. However, if very large surfaces are to have diffuse-reflective properties, for example in the case of large reflector panels for calibrating sensors, we believe that a coating of barium sulfate (BaSO4) is an alternative. This is because barium sulfate coatings can be simply sprayed onto the surface, like a paint, because we process the material as a ready-to-spray dispersion. However, this technique also has a serious disadvantage, in addition to the slightly lower diffuse reflection compared to Optopolymer®: barium sulfate coatings are subject to abrasive wear, which means they are much less resistant to mechanical stresses such as emerizing or machining than Optopolymer®. You are not sure whether Optopolymer® or a barium sulfate coating is the right choice for your application? Our experts know the answer from their many years of experience with photonic applications and will be happy to advise you!

Durable, robust and dimensionally stable

Optopolymer® PTFE from Berghof is far superior to other materials not only in terms of its optical properties, but also in many other respects. Our Optopolymer®, like our virginal polytetrafluoroethylene, is extremely UV-stable, water-repellent and resistant to almost all chemical compounds. This makes the optical materials and coatings produced by Berghof very durable and resistant to environmental influences. One of the key features of our Optopolymer® PTFE is its mechanical strength. By being processed in the press-sintering process, it obtains its robust material structure, comparable to that of HD polyethylene. This structure ensures good mechanical workability. This enables us to develop and manufacture self-supporting solutions for you that are far superior to those of simple reflective surfaces such as lacquers with added reflective pigments or titanium oxide coatings, not only in terms of diffuse reflection behavior, but above all in terms of durability, while at the same time offering all the outstanding properties of PTFE.

Broad spectrum: Berghof products for photonics

We already offer a wide range of proven solutions for this future market - and are constantly working with our customers to develop further ideas based on our Optopolymer® solutions. Our product range includes white references in the form of reflection standards and reflection targets, diffuse reflection and transmission films, integrating spheres, reflectors for solid-state lasers, laser cavities, high-quality projection surfaces and many other optical components. Due to the recent acquisition and integration of Gigahertz-Optik GmbH, a company that has been nationally and internationally successful with metrological solutions for optical radiation in industry for more than 30 years, Berghof is more than ever the right partner to optimally support you in your projects in the field of optical metrology.

We are already the partner of choice for customers in the following areas of optical materials - and the unique properties of Optopolymer® and our profound expertise ensure that new fields of application are constantly being added.

Optical metrology

In order to be able to precisely evaluate light sources and their optical radiation or the transmission of translucent materials not only in terms of light quality, but above all in terms of their direction-dependent radiant power, not only specialized contract lighting laboratories, but also more and more companies are using optical measuring instruments and systems in their own development departments, such as those developed and manufactured by our new sister company Gigahertz-Optik.

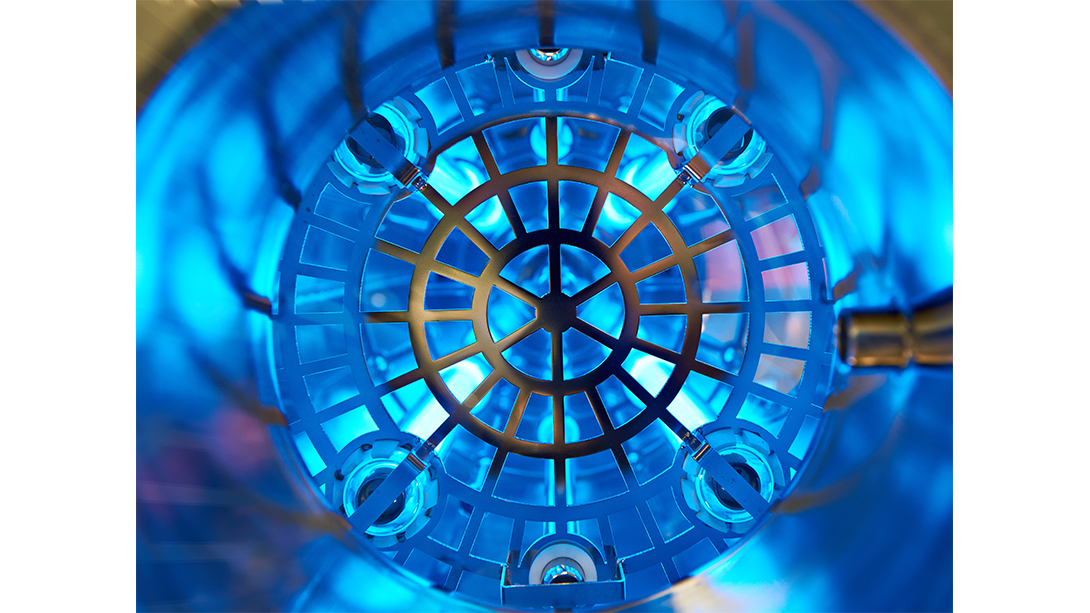

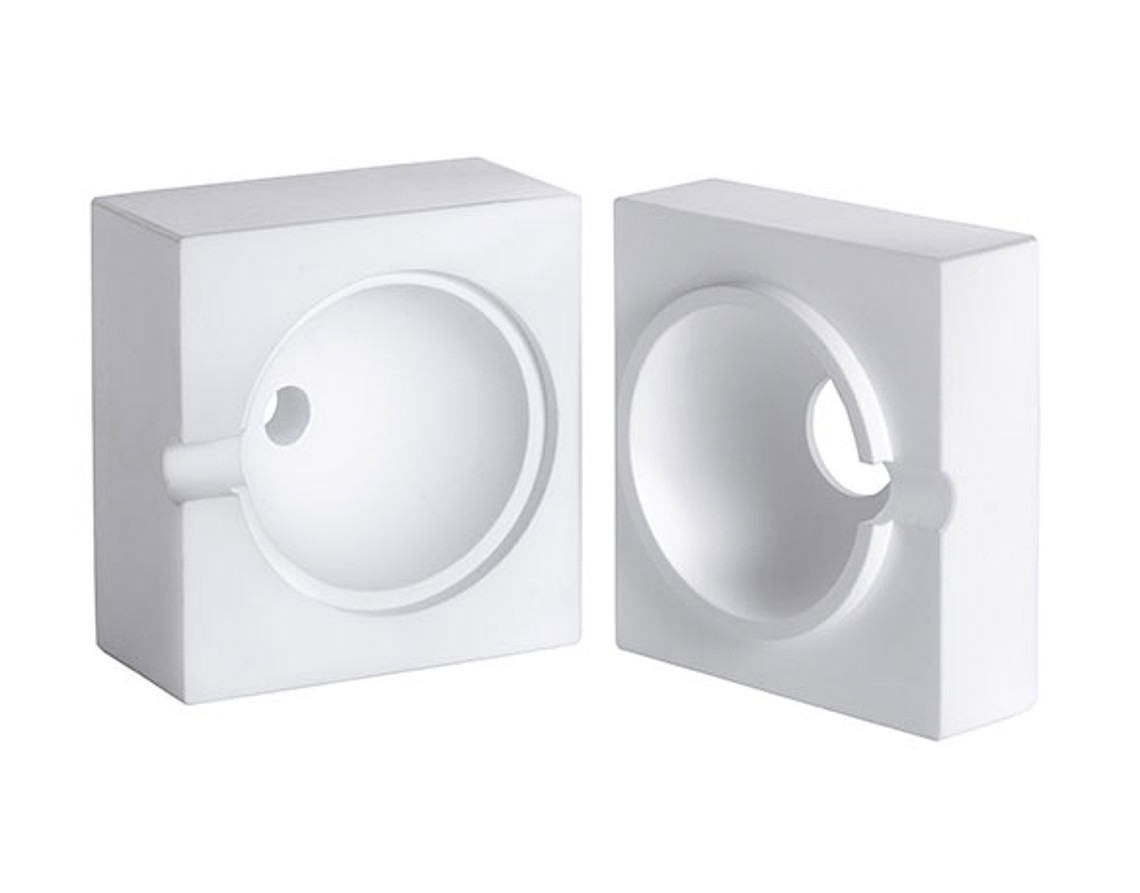

Very common are, for example, so-called spectrophotometers with which the light transmission of vehicle windows of all kinds can be determined with high precision, or spectral and broadband light meters for measuring illuminance (lux), luminance (cd/m2), luminous flux (lumen) and luminous intensity (cd). Our specialty in this area are self-supporting integrating spheres even in very complex geometries, which we develop and manufacture from our Optopolymer® for these optical measuring instruments. In most cases, we manufacture these integrating spheres as well as the associated accessories exactly according to the drawings provided by our customers - from single units to large series. An important Berghof specialty: our special manufacturing process enables us to use the high-quality Optopolymer® PTFE in larger geometries by pressing near-contour blanks in the so-called isostatic pressing process in a very material-saving manner - after all, the material is simply too good and valuable to be literally powdered.

UV-C-Sterilization

Not only since the Corona Pandemic the topic infection protection moved more than ever into the consciousness also the broad public, UV systems for the sterilization of surfaces, air and water are strongly in demand. And so the demand for our Optopolymer® is also increasing in this market because we use it to manufacture high-performance reflectors for systems for sterilization with UV-C light. The advantage of these PTFE reflectors from Berghof is that our special diffuse reflector technology with its extremely high efficiency enables manufacturers of UV systems for sterilization to achieve considerable savings in the area of UV lamps. This ensures that the higher purchase costs for these high-tech reflectors are quickly recouped. Lining the UV-C systems with our ideal diffuse reflector foils has another important advantage: thanks to the homogeneous illumination without shadows, the systems work much more efficiently, which means that manufacturers can build them much more compactly, because, for example, the exposure time of the UV-C light over the distance of an air stream disinfection does not have to be so long to achieve the desired result.

Laser Applications

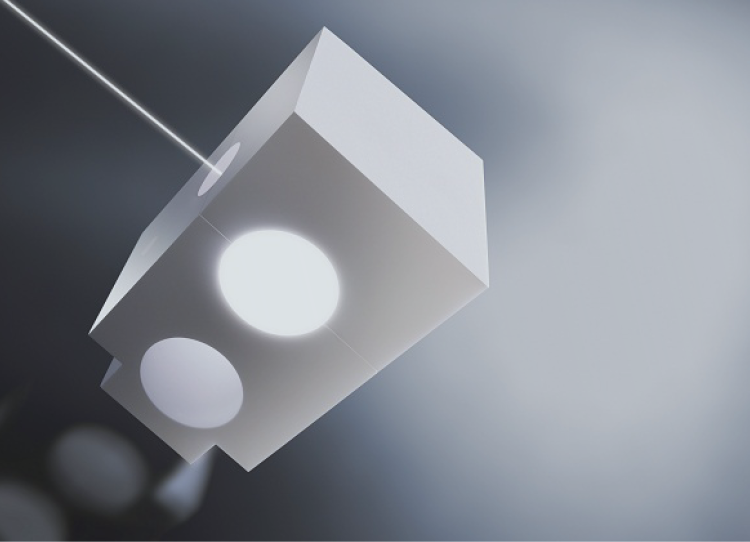

Highly flexible, contactless, wear-free: In industrial material processing, the manufacturers of modern production machines use the possibilities of laser radiation for increasingly sophisticated designs with the highest productivity, which make conventional production methods look old in the truest sense of the word. In medical technology, laser applications help doctors to analyze diseases faster and more precisely and to treat them better. Examples include laser surgery, where laser beams replace the scalpel, or pulsed lasers for cutting and ablating bone and cartilage. At the heart of these high-precision laser applications are the laser resonators, usually referred to as laser cavities. As the term resonator already suggests, the developers want to further increase efficiency with the help of the laser cavity by achieving the highest possible diffuse reflection. The aim is to maximize the performance potential of a laser system.

Extreme PURITY AND REDUCED Speckle-Effect

For the design of such high-power laser cavities, it is most important that the materials used are so pure that they do not offer any possibility of coupling to the energy-intensive irradiation. This requires, on the one hand, high-purity basic granulates and, on the other hand, a manufacturing process under controlled conditions. We manufacture laser cavities made of Optopolymer® exactly according to your design drawing, from one-off production to series production. With their uniquely high diffuse reflection, they contribute to outstanding results of your laser system and are also extremely resistant. Another field of application for Optopolymer® is projection surfaces for laser systems. Here, the aim is to reduce the undesired speckle effect of lasers, which occurs when projecting onto a surface, and thereby increase the contrast when projecting lasers. With our projection surfaces made of Optopolymer®, this speckle effect is almost completely eliminated. This is due to the volume reflection, which enables us to achieve different propagation times of the laser light.

Aerospace industry

Admittedly, the title for the blackest black, according to the Guinness Book of Records, has a different material. However, our Black Optopolymer® comes quite close to this difficult-to-get and therefore practically unheard of material in industrial practice, and has made a name for itself worldwide and even beyond as a proven and excellent "last-but-not-one" material with its ability to absorb ≥ 98% of incident light and this is to be understood quite literally. The American space agency NASA, for example, is one of Berghof Fluoroplastics' customers. In order to minimize the disturbing influences of direct sunlight or reflected scattered light when taking pictures, NASA engineers set out to find a material that would absorb light as well as possible and at the same time reduce its thermal effects - and after extensive testing they decided on Berghof's Black Optical PTFE. Applied to large areas of the satellite's optical instruments and other surface components, Berghof's Black Optopolymer® ensures that the measuring systems can operate without interference during the "OSIRIS-Rex" mission and that the satellite can land safely on the asteroid "Bennu". But that's not all: NASA has already contacted Berghof for further projects based on their positive experience with our Black Optopolymer®.

Autonomous driving

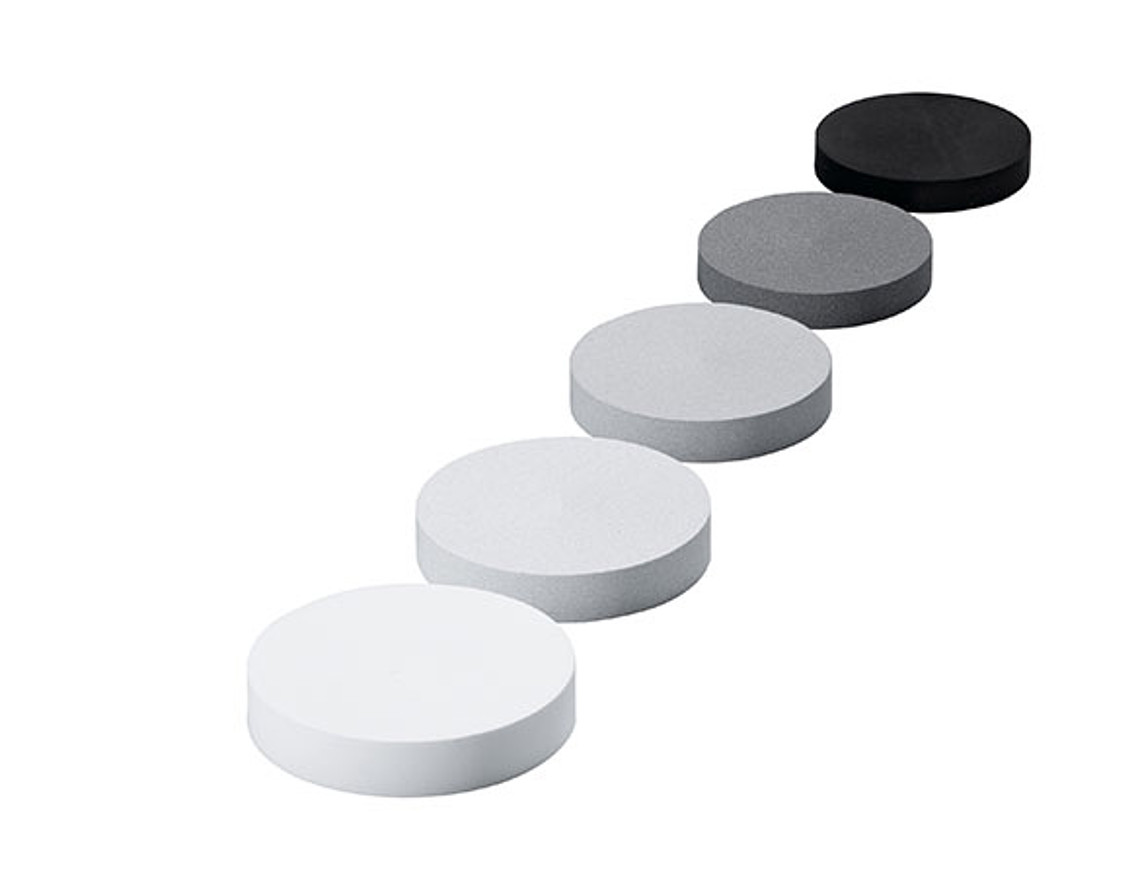

Optopolymer® also plays a key role in the future of autonomous driving. Have you ever wondered how self-propelled cars "see"? The magic word is LiDAR (abbreviation for "Light detection and ranging)" - and it is not without reason that it sounds almost the same as radar. Because the basic principle is very similar: To enable autonomous vehicles to permanently monitor their surroundings and react quickly and reliably to obstacles or other events that stand in their way, they are equipped with numerous 3D LiDAR sensors all around them for measuring distance and speed. While radar systems work with radio waves, LiDAR systems use laser beams. To ensure that these optical sensors will always function precisely in everyday life later on, they have to be calibrated precisely at the factory before the vehicle is delivered. Reflection standards made of Berghof Optopolymer® in black, white and in various gray scales are the preferred means of calibration for many customers because they can be produced with absolute precision in the defined gray scale. With their almost ideal Lambertian reflection behavior, they are independent of the angle of incidence of the light and are therefore ideal for calibrating optical sensors.

In-line calibration of sorting systems

Automatic sorting is playing an increasingly important role not only in industry, but above all in our daily lives. A well-known example are the vending machines for the return of deposit bottles (automatic reverse vending systems), in which optical systems take over the assignment of bottles to certain deposit categories. In the industrial sector, automatic sorting is particularly in demand in two areas: in optical quality assurance, for example of food, seeds or grain, and in the sorting of recycling materials. In the first case, the aim is to detect and sort out damaged or unwanted elements. In the second case, the task is to sort the waste according to material so that it can be optimally recycled. In this case, our customers use reflection standards made of Berghof Optopolymer® because of their unique, diffuse reflection in defined gray scales from 2% to over 99% reflection for so-called in-line calibration. This means that these automatic systems use our diffuse reflection standards to calibrate the installed cameras, spectrophotometers and other optical sensors quickly and with high precision. This saves time and money for the operator of the sorting system, because these systems, with their permanent in-line calibration, extend the intervals for regular calibration by an external service provider or sending the system to a calibration laboratory.

![[Translate to English:] Produkte aus Optischem PTFE [Translate to English:] Produkte aus Optischem PTFE](/fileadmin/_processed_/6/5/csm_Kachel_Optisches_PTFE_360x260_0432874aee.png)

![[Translate to English:] Werkstoffe [Translate to English:] Werkstoffe](/fileadmin/_processed_/7/d/csm_BFT_Werkstoff_kachel_u_c78e21dabb.png)

![[Translate to English:] Branche Automotive [Translate to English:] Branche Automotive](/fileadmin/_processed_/1/f/csm_Auto_Aussen_Kachel_Automotive_01_875cb1747e.jpg)