Due to the processing using the press-sinter process, Optopolymer® by Berghof gets its robust material structure, comparable with the one of HD Polyethylene. This structure provides a good mechanical workability. Therefore, we can manufacture dimensionally stable reflectors and engineered parts in various geometries with this material – for example self-supporting integrated spheres or laser cavities. During processing, the special, lambertian surface structure remains; it makes our Optopolymer® PTFE a material with the highest known diffuse reflection of up to >99 percent in the UV-VIS-NIR range. Berghof Fluoroplastics offers a variety of options in mechanical processing. Starting with quick prototypes up to the implementation of large-scale production – we are always the right partner!

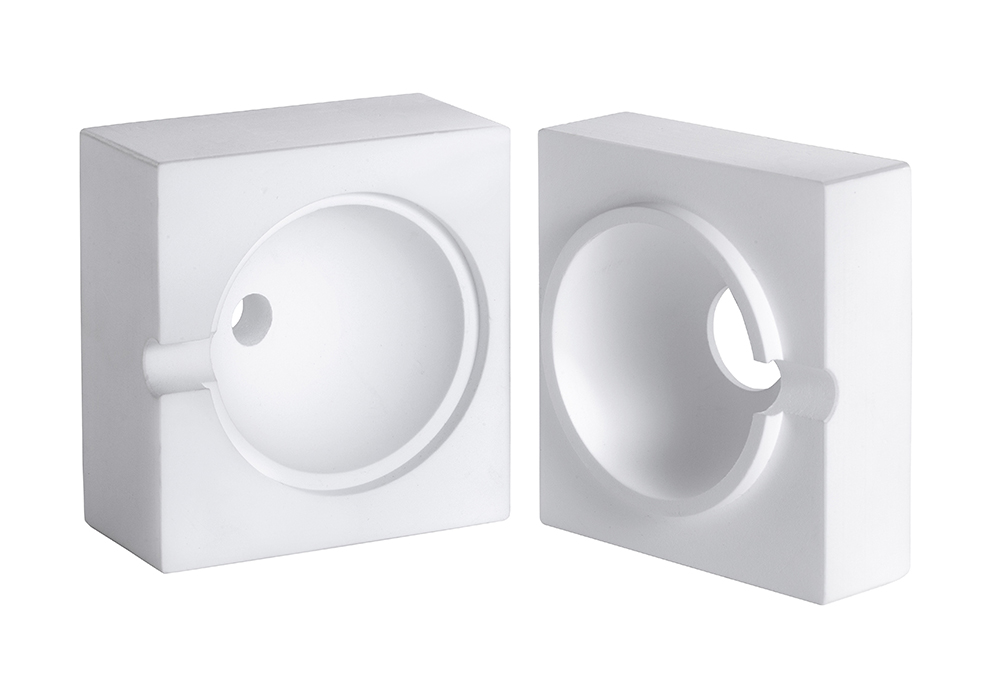

Integrated Spheres

The unique diffuse reflection properties and the mechanical stability of our Optopolymer® PTFE makes it the ideal material for reliable optical measurements. Berghof produces for example complex spherical geometries that are the centerpiece of optical measurement instruments such as spectral photometers. However, it is also used for self-supporting integrated spheres. Typically, we manufacture Optical PTFE integrated spheres and accessories based on drawings. For larger geometries, isostatic molding with precise contours allows a ressource-friendly use of this high-quality material.

Advantages

Extremely diffuse reflection of up to >99 %R, evenly across a wide wave length of ~250–2,500 nm

- Robust surface, more robust against abrasion than comparable surface coatings

Surface homogeneity +/– 1 %R

High energy density limit of up to ~8 J/cm² (laser damage threshold)

Temperature resistance of –200 to +260 °C (termporarily +300 °C)

Highest UV stability and universal chemical resistance, no discoloration

Dimensionally stable and flexible in shape

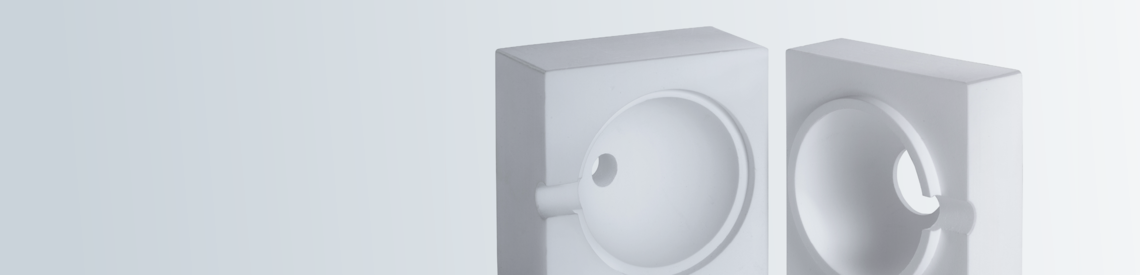

Laser Cavities

High-performance laser cavities made from Optopolymer® PTFE have an almost ideal lambertian, diffusely reflecting surface, and are so pure in their material composition that they do not give the energy-intensive laser radiation any opportunity to couple in. As a volume reflector with unique surface properties, Optopolymer® ensures optimum power yield from laser systems. That is why our laser cavities made from Optopolymer® are the first choice of many laser developers.

Advantages

- Extremely diffuse reflection of up to >99 %R, evenly across a wide wave length of ~250 – 2,500 nm

- Robust surface, more robust against abrasion than comparable surface coatings

- Surface homogeneity +/– 1 %R, no speckle-effect

- Irradiation cannot couple

- High energy density limit of up to ~8 J/cm² (laser damage threshold)

- Temperature resistant between –200 and +260 °C (+300 °C short term)

- Highest UV stability and universal chemical resistance, no discoloration

- Dimensionally stable and flexible in shape

Applications

- Pulsed lasers

- Laser modulators

- Phase modulators

- Cross lasers

- Diode lasers

- Sensor lasers

- Disk lasers

![[Translate to English:] Werkstoffe [Translate to English:] Werkstoffe](/fileadmin/_processed_/7/d/csm_BFT_Werkstoff_kachel_u_c78e21dabb.png)

![[Translate to English:] Folien aus Optischem PTFE [Translate to English:] Folien aus Optischem PTFE](/fileadmin/_processed_/9/8/csm_Folien_kachel_01_7aa307cabb.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/0/csm_Coating_Services-Teaser_360x260_alternativ_b609c1f008.jpg)