Without the required pressure equalization, differences in pressure occur between housing and sorroundings and can lead to leakage and as a result to damages of the housing. Permeaflon® venting membranes in different shapes, sizes and designs ensure constant pressure equalization. At the same time, they prevent the penetration of foreign substances such as water, dirt and even oils. Berghof membanes resist even under harshest conditions, like jet-water, heavy rain and temporary plunging. We flexibly adjust our membranes to the housing that needs to be ventilated. Merely a corresponding hole is necessary in order to exactly apply the venting membrane to the housing.

Advantages

Even challenging automotive applications, also in the engine environment, can be realized with Permeaflon® venting elements. They are extremely temperature resistant from –200 to +260°C and resistant against practically every media used in the automotive environment. Upon request, the membranes are also available as double-sided oleophobic (oil repellent). Our membranes comply with IP67 and IP68 requirements (higher protection classes depend on the housing design).

Applications

-

Lighting

-

Energy technology

- Packaging

-

Telecommunication systems

-

Transport and safety systems

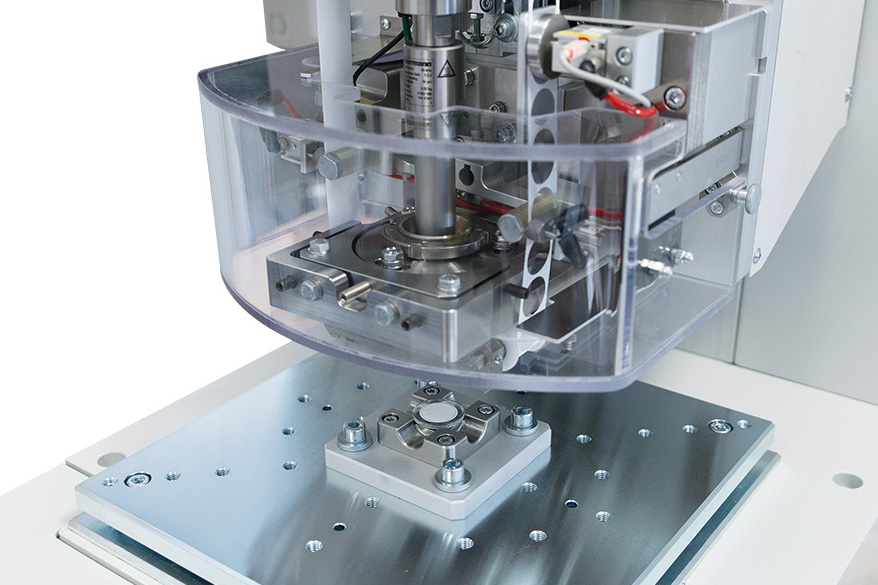

Highest quality standards

![[Translate to English:] 100% Prüfung von Membranen](/fileadmin/_processed_/7/2/csm_BFT_Kompetenzen_Forschung_330ac2dc55.jpg)

As a partner for customers from many different industries and a qualified supplier of the automotive industry, our production processes and management system are certified to DIN EN ISO 9001:2015 and IATF 169496:2016.

Downloads

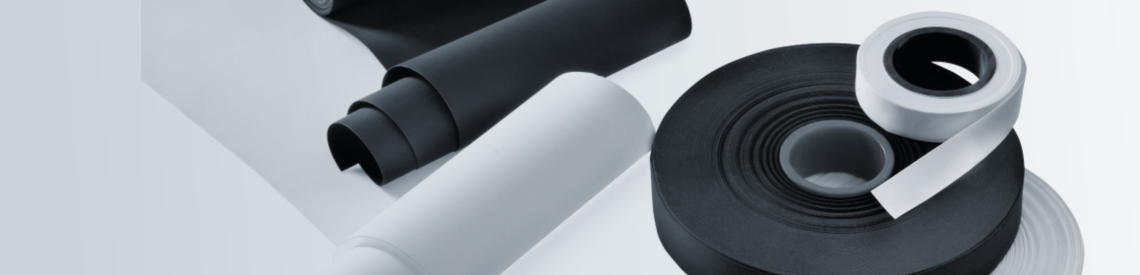

Weldable Membranes

Venting membranes made from porous PTFE can be excellently welded on plastic parts, thermally or using ultrasonic technology. Welding enables a highly durable connection between the membrane and the component, even under harshest conditions. The membranes ensure reliable venting and protect the housing against penetrating liquids or dirt at the same time.

Advantages

Shorter cycle time during processing

Customized forms and sizes

Stampings or tapes available

Safe and reliable connection between component and membrane using ultrasonic sealing

Highest chemical and thermal resistance

Self-Adhesive Membranes

Self-adhesive venting membranes consist of a membrane and a pressure-sensitive adhesive ring. Through this adhesive ring, the membrane can be applied directly to the component without using any additional substances. The self-adhesive membrane allows easy handling and a fast application without further drying time. Constant pressure equalization is hereby ensured.

Advantages

-

Reliable adherence due to adaptable adhesion stength

-

Standardizes sizes 3 mm to 14 mm

-

Customized forms and sizes

![[Translate to English:] Kabelverschraubungen PermeaGland® [Translate to English:] Kabelverschraubungen PermeaGland®](/fileadmin/_processed_/8/4/csm_BFT_Kabelverschraubung_Permea_gland_kachel_5f6425b63c.jpg)

![[Translate to English:] Ventilkappen PermeaPlug® [Translate to English:] Ventilkappen PermeaPlug®](/fileadmin/_processed_/4/b/csm_BFT_Ventilkappen_PermeaPlug_a40ebcd763.jpg)

![[Translate to English:] Branche Automotive [Translate to English:] Branche Automotive](/fileadmin/_processed_/1/f/csm_Auto_Aussen_Kachel_Automotive_01_875cb1747e.jpg)