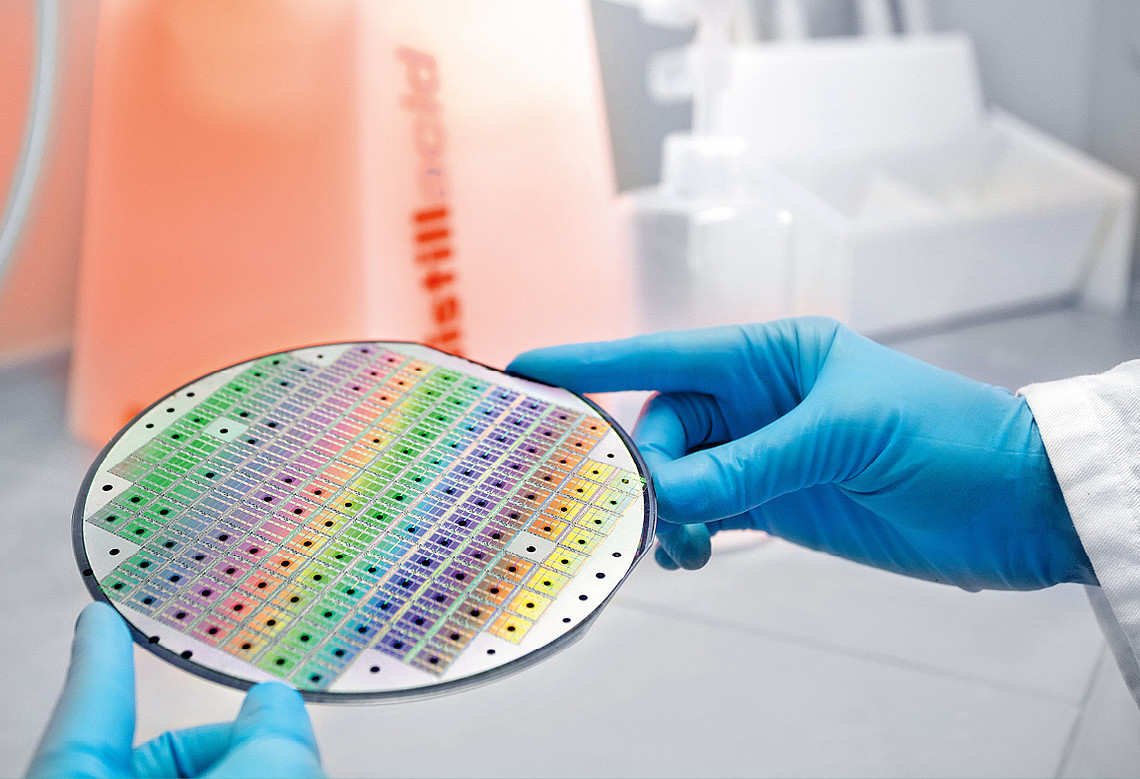

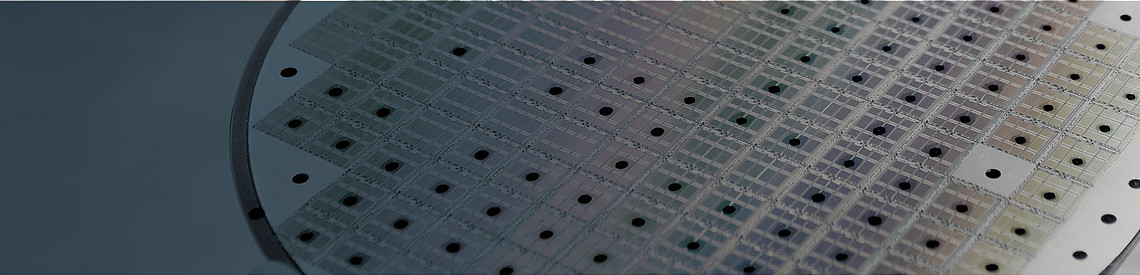

Parts in the semi-conductor, galvano and wet process technologies are becoming smaller and more complex all the time. The processing methods pose the highest demands to process cleanliness and safety. Even small contaminations can massively impair the function of electronic parts. Shorter throughput times increase economic efficiency, while the equipment used must be able to resist the increasingly aggressive etching media at rising process temperatures. Efficient process solutions are needed in order to implement the required quality standards, high throughput rates and short downtimes.

Long-lived, resilient, resistant

Wet-process equipment of PTFE by Berghof meets all requirements to chemically inert, pure and highly efficient processing processes across a wide temperature range. The contamination risk is lower than in any alternative material thanks to extremely smooth surfaces. The resilient, seamlessly isostatically pressed vessels are long-lived and do not need to be treated with an expensive coating or elaborately finished.

Advantages

- Unique quality of isostatically pressed formed parts of PTFE / modified PTFE

- No carrying of metal ions in the wet process or in the material due to un-extruded PTFE

- Lowest permeation rate of O3 into the isostatically compressed, smooth surface structure

- Protection against aggressive media from near-universal chemical resilience

- Simple cleaning of the vessel systems due to their extraordinary anti-adhesive properties

- Long service life of the parts through particularly narrow production tolerances

- High process safety

- Etching container systems and component carriers are available in diverse forms and sizes

- Outstanding price-performance ratio

- Berghof is an established manufacturer of wet-process equipment and system solutions made of PTFE

Highest cleanliness

Berghof relies on a production method that excludes all contamination with metal ions. Sintering of PTFE takes place at room temperature and in block form; subsequent cutting requires no lubricants. In contrast to the processing process of, e.g., PFA, PTFE and modified PTFE will not have full-surface contact between the parts and the hot metal components, even in the gel condition. In addition to this, the cutting behaviour permits faster and more economically efficient product development as compared to PFA.

![[Translate to English:] Nassprozess-Equipment aus High Density PTFE [Translate to English:] Nassprozess-Equipment aus High Density PTFE](/fileadmin/_processed_/2/1/csm_NassprozessEquipment_Kachel_2_01_9ff9cbcab9.jpg)

![[Translate to English:] Werkstoffe [Translate to English:] Werkstoffe](/fileadmin/_processed_/7/d/csm_BFT_Werkstoff_kachel_u_c78e21dabb.png)

![[Translate to English:] Kompetenzen [Translate to English:] Kompetenzen](/fileadmin/_processed_/a/a/csm_BFT_Kompetenzen_kachel_f9d0a14568.jpg)