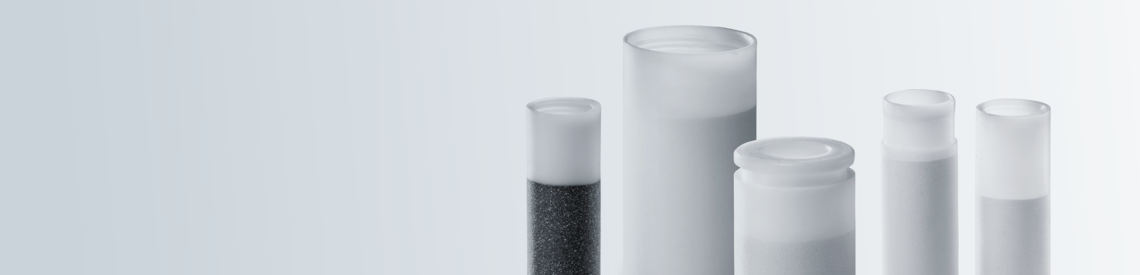

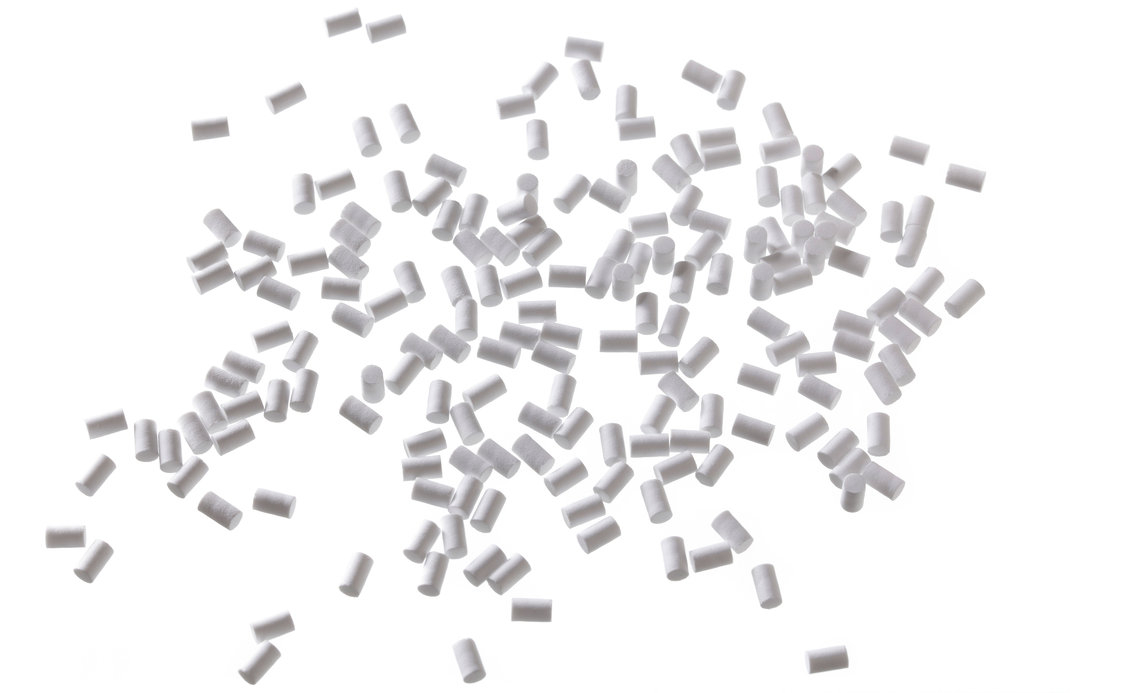

We are producing symmetrical porous Permeaflon® filter elements made from pure PTFE granulate using a press-sinter process. Therefore, our filter elements combine the outstanding characteristics of the material PTFE and a good mechanical inherent strength. This is why we are able to process them into a variety of specific filter elements with our highly modern machinery. The special feature of Permeaflon® filter elements: Their homogeneous, adjustable porosity results in an ideal gas permeability and a hydrophobic and anti-adhesive behaviour at the same time. Moreover, our filter elements are chemically inert and highly thermally resistant. Thus, they can even be used in industry sectors with highest requirements.

Advantages

- Filter elements made from porous PTFE; sintered for highest mechanical inherent stability

- Self-supporting and self-sealing

- Isostatically molded, for homogeneous porosity

- Adjustable pore size between ~1 and 100 µm

- Standard filtering degrees: 2 and 20 μm nom.

- Extremely hydrophobic und optionally oleophobic

- Highest chemical resistance

- Physiologically harmless, suitable for food contact

Applications

Berghof manufactures self-supporting and self-sealing Permeaflon® filter tubes in different wall thicknesses and porosities for installation in filter housings. The main applications of Berghof’s filter elements are as so-called diaphragms or HPLC filters in the analysis technology. Their high purity provides contamination-free measurement results and their adjustable porosity ensures optimal response times of gas sensors. Furthermore, our filter tubes serve as standard filters at gas filtration, even for highly aggressive gases. In this case, their task is to filter smallest particles and aerosoles during the process. Another typical application: our hydrophobic filters ensure consistent gassing of liquids in gas-liquid-separation processes or aerators, for example in the chemical or food industry.

Filter tubes

Exactly adapted to the specifically required filtration efficiency and separation efficiency and produced in consistently high quality: Berghof manufactures self-supporting and self-sealing filter tubes made of Permeaflon® in different wall thicknesses and porosities for customers from various industries, mostly for installation in filter housings of all kinds. With PTFE filter tubes in particular, Berghof has successfully established itself in the field of gas filtration with standard dimensions. Our material solutions reliably filter the smallest particles and aerosols, even from highly aggressive, corrosive process gases. Installed as the main component of line filters or for the purpose of sample gas treatment, they protect sensitive electronics and sensor components. Another typical area of application for Permeaflon® filter tubes from Berghof: Our hydrophobic filter tubes ensure the uniform gassing of liquids in gas-liquid separation processes or perlators, for example in the chemical or food industries. This is because our PTFE filter tubes are physiologically harmless and therefore even suitable for contact with food - just one of the many outstanding properties of PTFE.

Ordering information

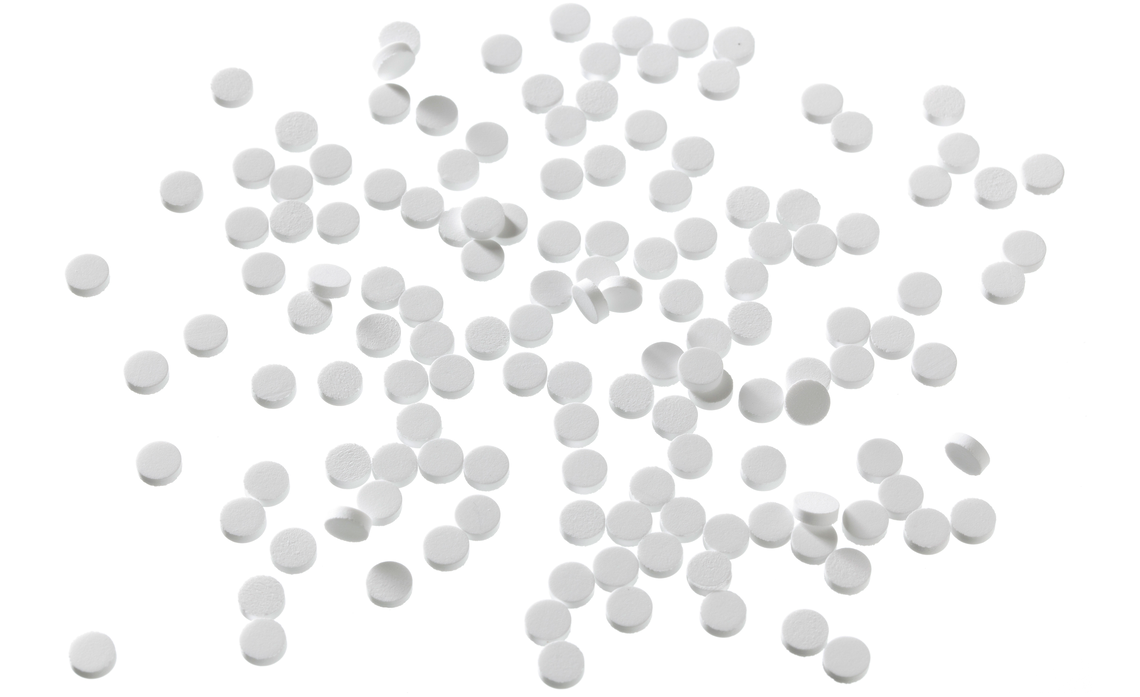

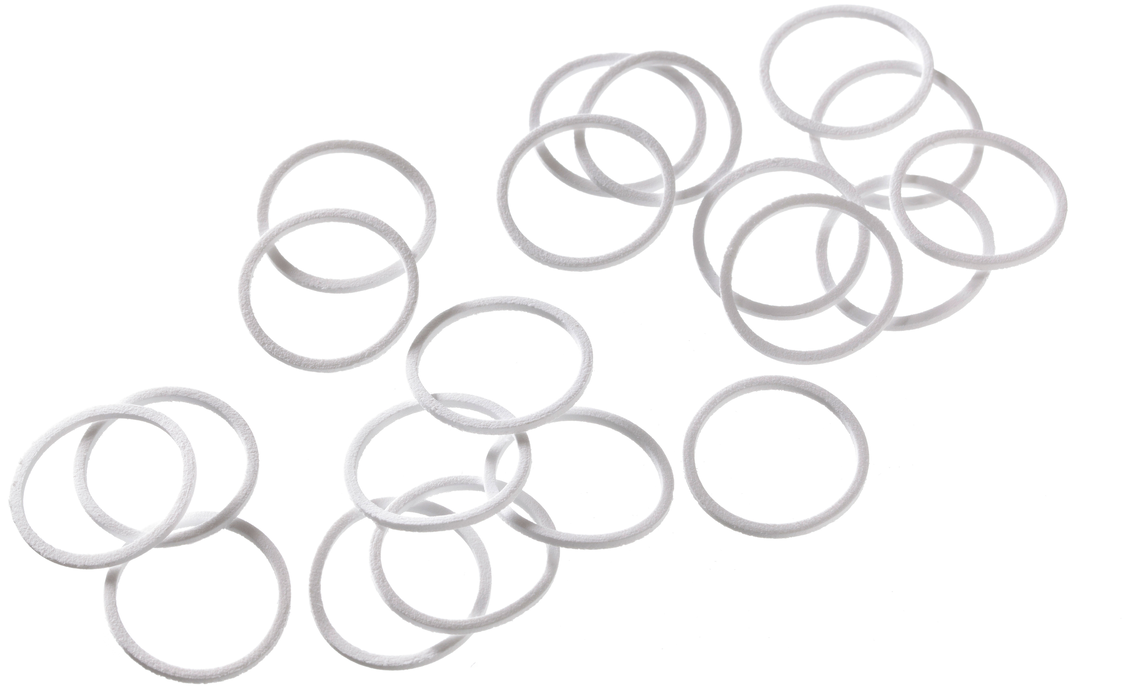

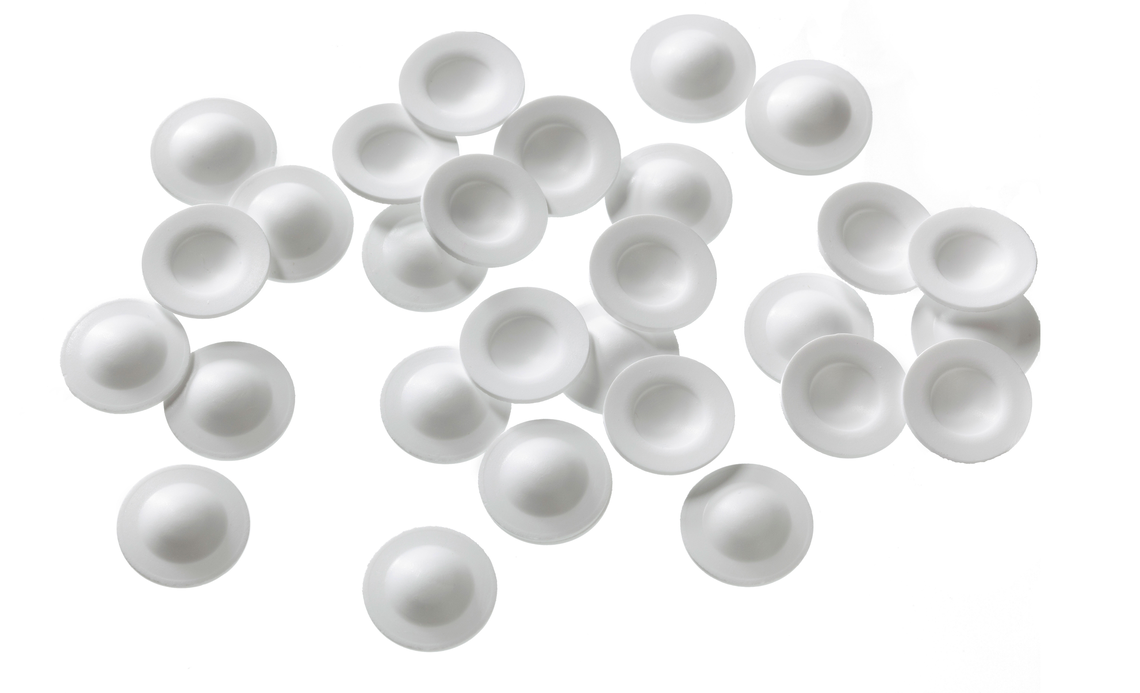

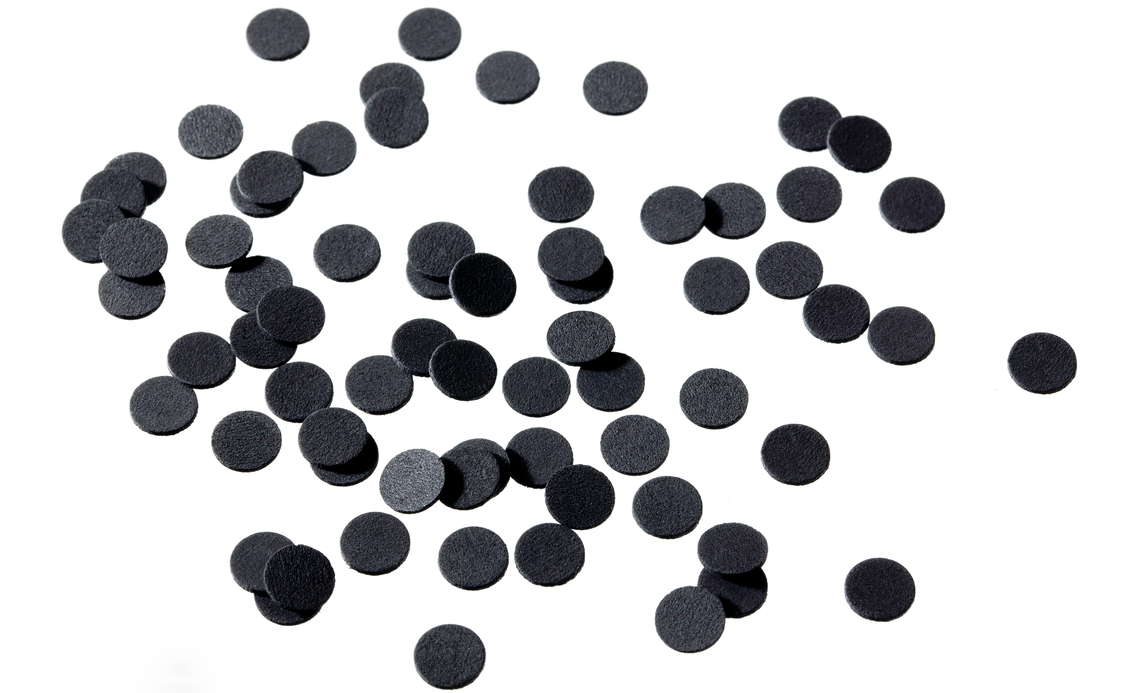

Sandwich filters

Berghof’s specialty: we combine virginal, massive with porous PTFE for filter elements with integrated threaded connectors. They can be screwed comfortably and self-sealing. The main use of hydrophobic and gas-permeable sensor protection caps by Berghof is the environmental metrology, where they protect the delicate sensors of measuring instruments from unintentional access and weather related impacts.

When it comes to sandwich filters, our experienced experts in our in-house development department and in our modern production facilities are really in their element - this is where we can really make the most of our expertise and experience with sophisticated, complex material solutions based on PTFE. In our sandwich filters, we combine our virginal, solid PTFE with Permeaflon®, our porous PTFE, to create hydrophobic and gas-permeable filter elements with an integrated threaded connection, which also score highly in terms of UV and weather resistance - one of the many special properties of PTFE.

The major advantage of this solution, which has been successfully tried and tested for many years in various industries and even under the toughest conditions, is that our sandwich filters can be screwed together easily and are self-sealing. The most important area of application for our sandwich filters is environmental measurement technology, where they are known and valued as sensor protection caps. With these sensor protection caps, our customers effectively protect the sensitive sensor technology of their measuring devices from unwanted access and the effects of the weather - and thus ensure repeatable, stable and accurate meteorological measurements. The measured values of the environmental measuring devices collected in this way then allow reliable conclusions to be drawn and help to precisely predict weather events such as fog, frost or dangerous black ice - and the environmental measuring devices are thus, for example, the heart and brain of the increasingly frequent use of flexible traffic signs, known in the jargon of traffic planners in the authorities as traffic control systems.

Our PTFE sandwich filters are also used in many other applications as sensor protection caps for temperature and humidity probes - such as in drying and test chambers in various industries. Another application is water vapor measuring devices, such as those used in the production of lithium batteries, to monitor the humidity in the production environment and thus ensure the perfect quality of the batteries.

![[Translate to English:] Branche Automotive [Translate to English:] Branche Automotive](/fileadmin/_processed_/1/f/csm_Auto_Aussen_Kachel_Automotive_01_875cb1747e.jpg)

![[Translate to English:] Werkstoffe [Translate to English:] Werkstoffe](/fileadmin/_processed_/7/d/csm_BFT_Werkstoff_kachel_u_c78e21dabb.png)

![[Translate to English:] Druckausgleichselemente aus Porösem PTFE Permeaflon® [Translate to English:] Druckausgleichselemente aus Porösem PTFE Permeaflon®](/fileadmin/_processed_/0/e/csm_BFT_druckausgleichelement_kachel_N_3d66ed481c.png)