One material – fascinating variety

With its unique positive properties, PTFE is one of the most diverse materials available. It is impossible to imagine technical applications without it. The sophisticated combination with additives, often called fillers, enables us to optimize and expand these unique properties even further.

Processing

Processing exerts a major influence on the molecular weight, crystalline structure and pore content of the moulded parts and, therefore, on their quality. Thus, it is important to take particular care at all processing steps. When processing PTFE, the following process steps are performed:

Compression

Sintering

Cooling

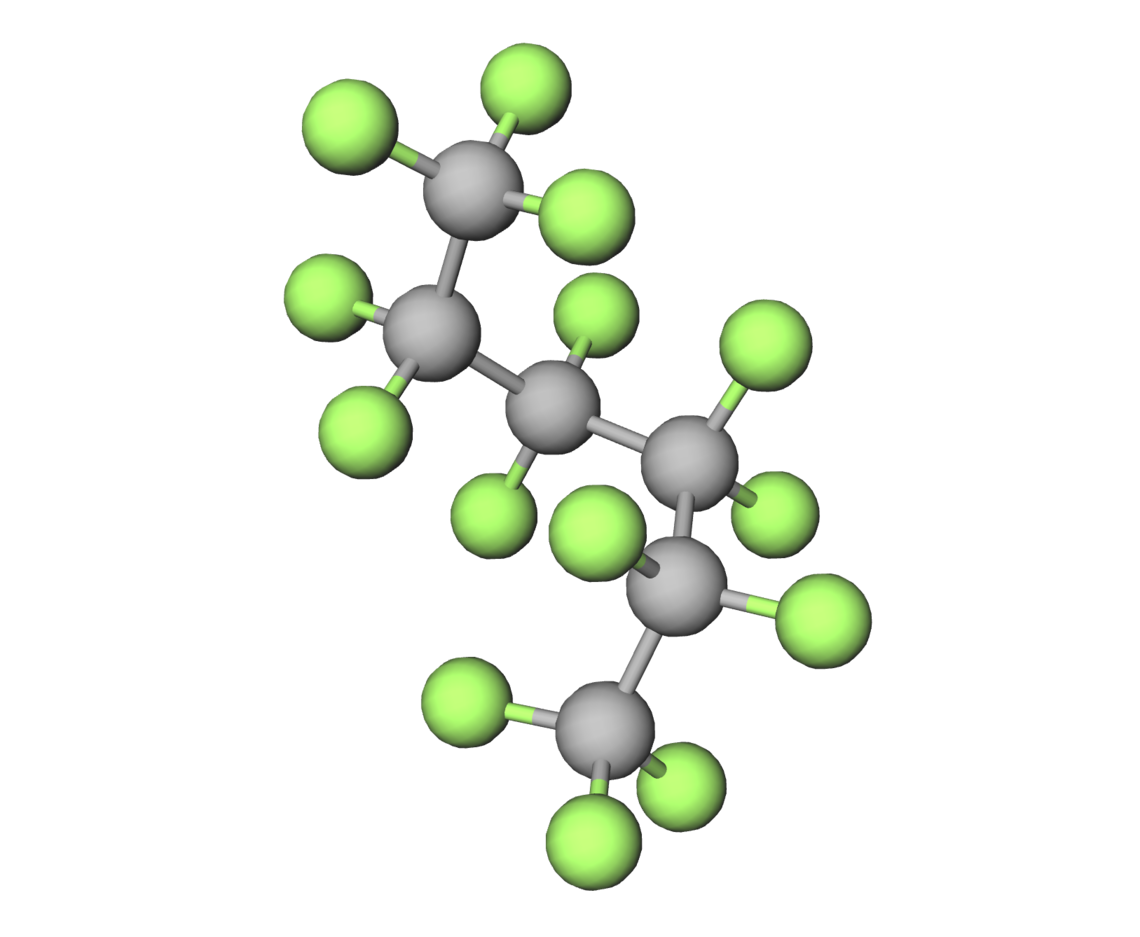

PTFE

Polytetrafluoroethylene (PTFE) is a chemically highly resilient fluoroplastic, and by far the most important one of its kind. The trademarks of PTFE are: TeflonTM, DyneonTM, Fluon®. Berghof Fluoroplastics uses these to produce products and material solutions in different forms and sizes, as well as a comprehensive range of accessories. When it comes to products made from virginal, isostatically pressed PTFE, we are talking about High Density PTFE (HD PTFE) for pointing out the unique quality and poreless character of the material.

Properties

- Temperature resistant between –200 and +260 °C in continuous operations

- Practically completely resistant to chemicals

- Extremely anti-adhesive

- Low coefficient of friction – no stick/slip effect

- Lowest relative permittivity and the lowest dielectric loss factor of any plastic, together with high specific transient resistance and surface resistance

- High UV and weather resistance

- Inherently flame-retardant UL 94 V-0

- Physiologically harmless

- Suitable for food contact

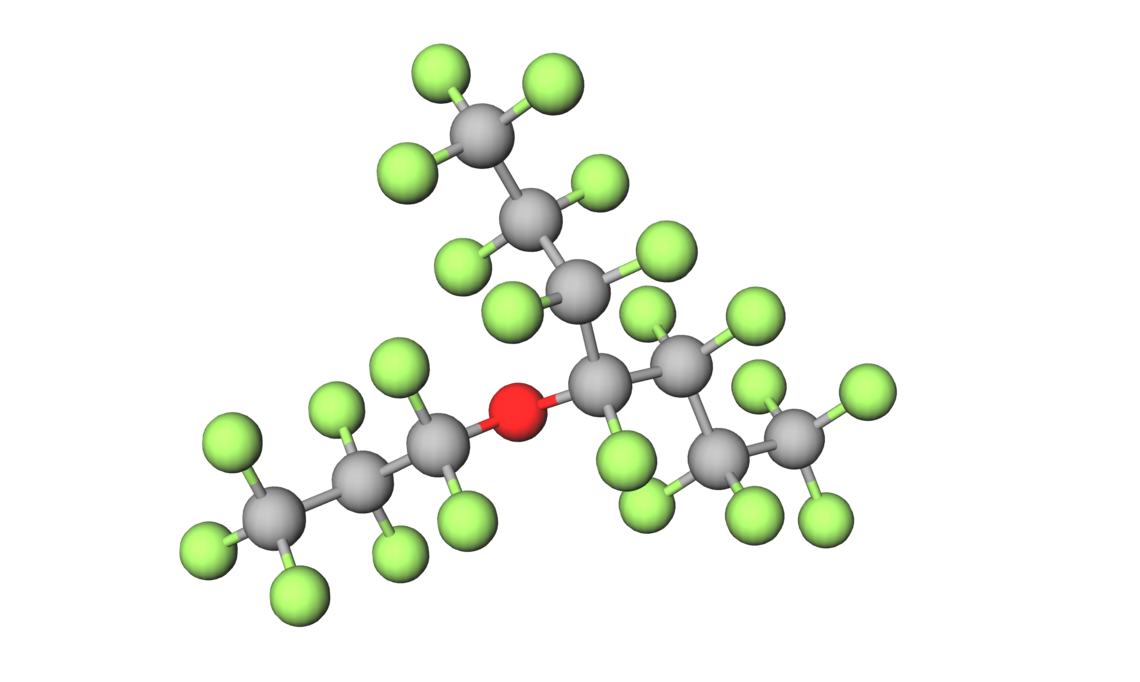

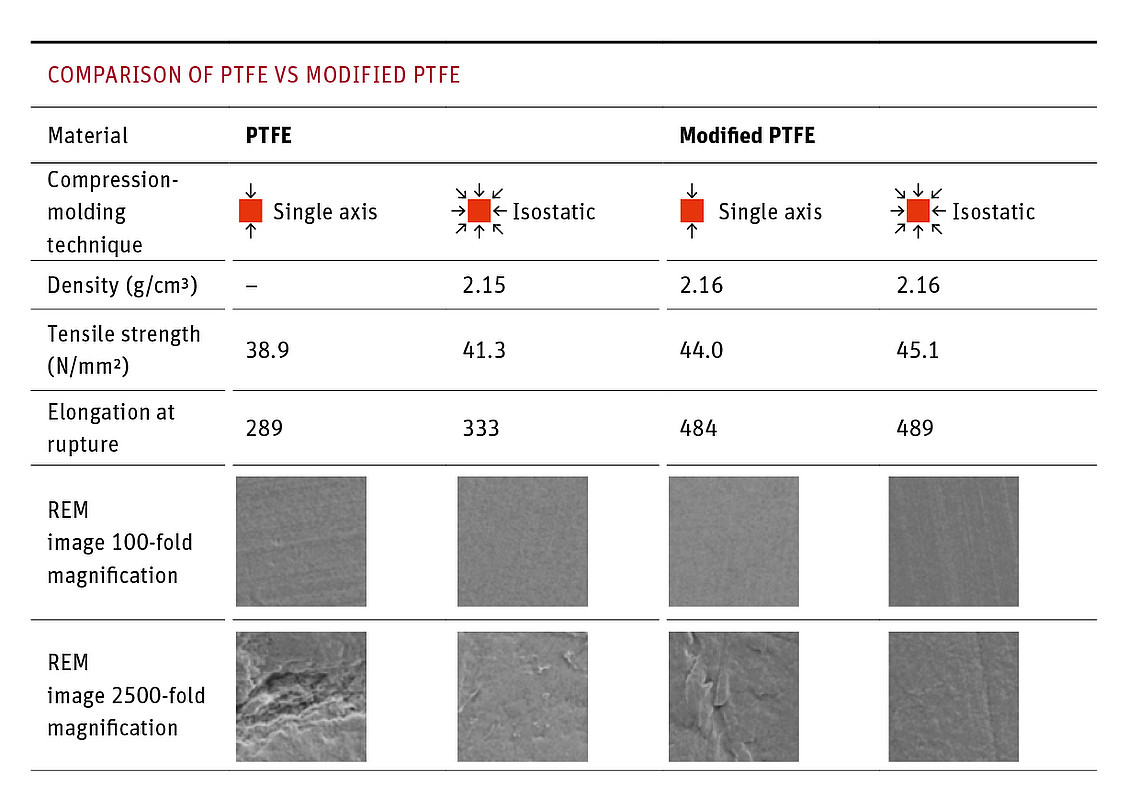

Modified PTFE

Modified PTFE ideally fills the “properties gap” between PTFE and PFA, without needing to be processed by injection moulding like PFA. It is also known under the trade name 3MTMDyneonTMTFMTM. The molecular weight is only approx. 1/5 that of PTFE, while PFA only has 1/100 of the molecular weight of PTFE. When it comes to products made from modified, isostatically pressed PTFE, we are also talking about High Density PTFE (HD PTFE) for pointing out the unique quality and poreless character of the material.

Extended Properties

- Low pore content, therefore lowered gas permeation rate than that through conventional PTFE and only a bit higher than that through PFA

- Improved surface characteristics compared to PTFE

- Better weldability

- Lower cold-flow properties

- Reduced stretch-void index

Applications

Modified PTFE is preferably used where closed surfaces without pores are of special importance. Products of modified PTFE with particularly smooth surfaces are of benefit when producing, transporting and storing ultra-pure chemicals, as well as in wet-chemical processes. Adhesion of differing substances is made more difficult, cleaning methods are much more efficient, and downtimes are much shorter.

PTFE Compound

Under the designation compound, Berghof offers a number of mixtures of PTFE, or modified PTFE with inorganic additives, which are often referred to as fillers. Compounds have developed into a reliable material for critical and highly specific applications. Selected fillers change the physical properties of PTFE or modified PTFE; and adjust them precisely to the specific application of the material.

Extended Properties

The area of use of PTFE compounds is growing continually. The many positive properties that we achieve by selected additives (fillers) result in an enormous competitive benefit compared with other materials. For example, our PTFE compounds achieve the following important optimisations:

- Higher pressure resilience

- Better heat conductivity

- Higher wear resilience

- Reduced thermal expansion

- Lower cold flow properties

Processing

Depending on the requirements of materials, Berghof Fluoroplastics adds various additives to PTFE. The following additives are particularly suitable out of the many options:

- Glass (usually in the form of short fibres)

- Coal

- Graphite

- Metal powder (bronze, chrome nickel steel)

- Molybdenum disulphide

- PEEK

- and mixtures of these

PTFE or modified PTFE compounds are offered in a pouring or non-pouring form. Processing corresponds to that of unfilled fluoropolymer, but higher pressures are required. Depending on the filler content, these pressures are between 300 and 700 bar; though they can rise up to 1500 bar in automatic pressing.

Depending on the type of additive and purpose of the mix, PTFE or modified PTFE compounds contain 0.2 to 60 vol% of the additive. It is important that the additives survive a temperature of +380 °C during sintering.

Applications

- PTFE/Mod. PTFE without fillers: In mechanical engineering, in electrical engineering, as insulation, in chemical equipment construction for seals and chemically resistant components, for bellows and laboratory equipment

- PTFE/Mod. PTFE with carbon: For hydraulic seal elements, for parts requiring good thermal conductivity, for pressure and wear resistant parts, for bearing bushes and seals, for valve seats

- PTFE/Mod. PTFE with graphite: Good thermal conductivity with adequate elasticity and good storage characteristics, for seal elements, especially lip seals

- PTFE/Mod. PTFE with fiberglass: Pressure resistant, even at higher temperatures, minimum cold flow, for chemical pumps, bearing bushes, and seals

- PTFE with Bronze: High pressure and wear resistance, especially well suited for bearings and guides

Download

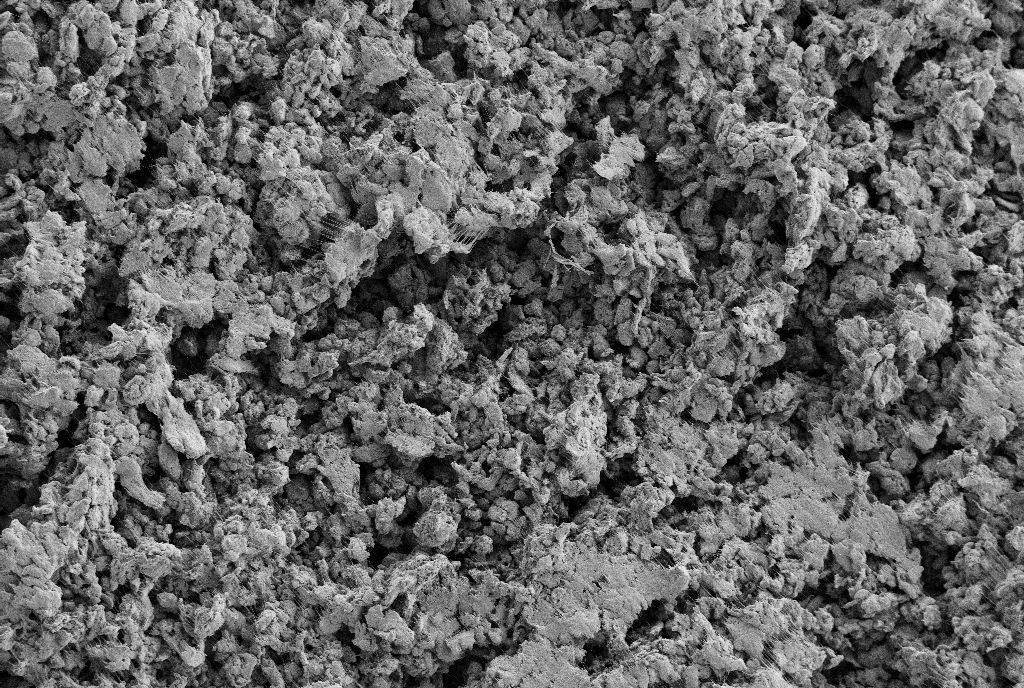

Porous PTFE

Berghof complements the unique properties of PTFE to a porous structure. An important innovation that has its own name: Permeaflon®. On the basis of Permeaflon® and by developing customized solutions, we open up new versatile fields of application in the field of porous materials.

Extended Properties

- Symmetrical porous structure (no preferred direction)

- Breathable, semipermeable

- Extremely hydrophobic

- Optional oleophobic

- Free from perfluorooctanoic acid (PFOA)

Processing

Thanks to the use of specially developed starting granules and production processes, Berghof is able to add porous properties to PTFE products. During manufacturing, Berghof’s porous PTFE is subjected to a sintering process at over 300 °C. This gives the products high temperature and dimensional stability. Thus, even the most demanding challenges can be met through the use of Permeaflon®.

Applications

Chemical and semiconductor technology:

- Filters for gases and liquids

- Catalyst supports / diaphragms

- Aerators for gas inlets and distributors

- Venting elements for containers and batteries

Filter and safety technology:

- Filter membranes

- Thermo wells

- Dust filters

- Sensor protection elements

- Silencers

Automotive and aerospace technology:

- Venting elements

- Sensor protection elements

Optical PTFE

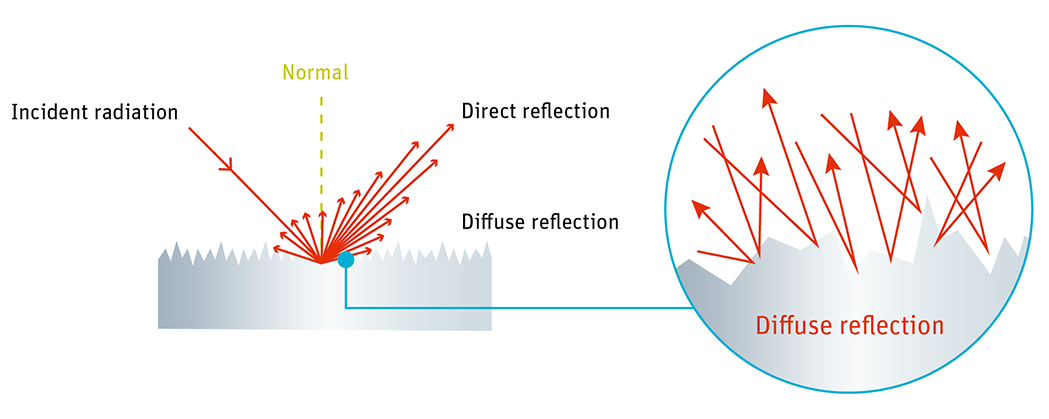

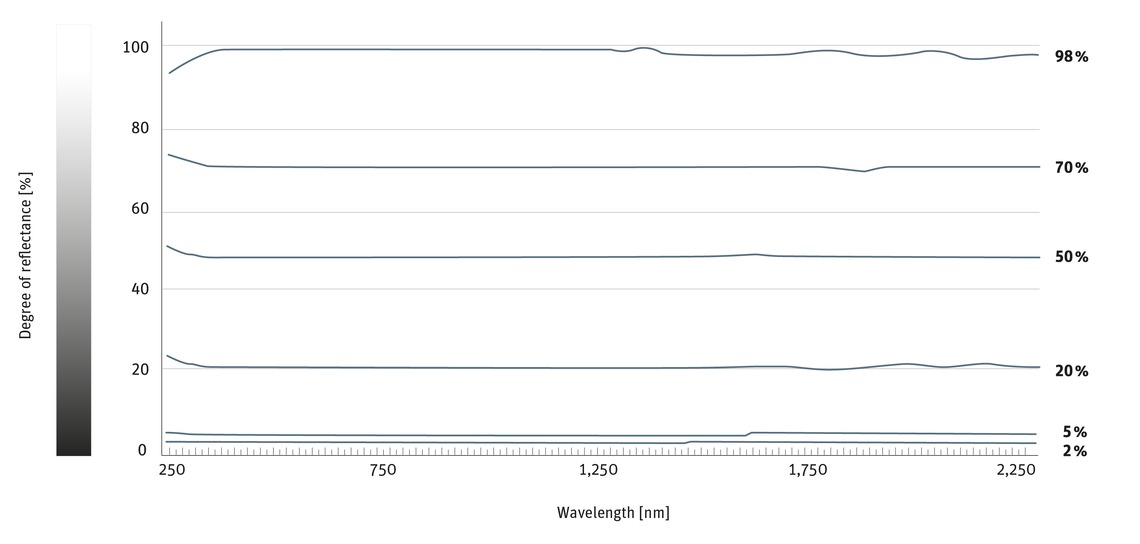

With its purity and outstanding surface structure, Optical PTFE by Berghof achieves a near-ideal Lambert’s reflection behaviour with a reflectivity of up to > 99 percent in a broad wavelength range of 250 to 2,500 nm. This makes it to the material with the highest known diffuse reflection.

Processing

The isostatic compression of the raw material ensures an absolutely diffuse reflection over the whole surface of the component. In addition, the outstanding properties of the PTFE such as its high thermal stability of –200 to +260 °C and its UV resistance protect the components against discolouration and embrittlement. This guarantees permanent dimensional stability and functionality throughout its long lifespan.

Applications

- Diffusely reflecting material

- Reflectance and fluorescent standards in gradations

- Lambertian reflectors and diffusers

- Laser cavities

- Integrated spheres

- UV drying chambers

- UV air and water sterilisers

- Background lighting for displays

- Reflectors and mixing chambers for LED and OLED

- Photobioreactors

![[Translate to English:] Produkte aus High Density PTFE [Translate to English:] Produkte aus High Density PTFE](/fileadmin/_processed_/1/f/csm_HD_PTFE_kachel_01_71acf1df55.png)

![[Translate to English:] Produkte aus Porösem PTFE [Translate to English:] Produkte aus Porösem PTFE](/fileadmin/_processed_/6/1/csm_BFT_druckausgleichelement_kachel_81fb31fee6.png)

![[Translate to English:] Produkte aus Optischem PTFE [Translate to English:] Produkte aus Optischem PTFE](/fileadmin/_processed_/6/5/csm_Kachel_Optisches_PTFE_360x260_0432874aee.png)