When people hear the word TeflonTM, they usually think immediately of frying pans. That’s a shame: Because polytetrafluorethylene (PTFE), the technically correct name for the material which is marketed under the brand name TeflonTM, can do a whole lot more than merely prevent food from sticking. Apart from the fact that PTFE is extremely anti-adhesive, it is distinguished above all by its immense chemical and thermal resistance.

For more than 50 years, Berghof Fluoroplastics has been dealing almost exclusively with this material. And they are constantly finding new, exciting areas of application in which PTFE convinces in customized solutions.

AdBlue® tank caps are an excellent example. Similar to fuel tanks, the tanks for AdBlue® also require an effective system for aeration and venting to compensate the internal pressure fluctuations caused by changes in temperature, filling level or position. This job is taken over by a venting element in the tank cap.

And a real all-rounder is required for this purpose because urea, the basic substance of AdBlue® has a strong crystallization tendency. Evaporation of water forms white crystals which can clog the venting membrane. So, ideally, the membrane should be designed in such a way that the urea solution drips off without residue to prevent crystals from adhering to it. In addition, the membrane must be extremely gas-permeable on the one hand and may not let through any liquids on the other hand.

There is a material which ideally unites exactly these properties: Permeaflon® from Berghof. Therefore, one of the leading manufacturers for sealing technology for the numerous AdBlue® tank cap variants of their well-known customers has subjected this high-tech plastic – the expert calls it symmetrically porous, sintered PTFE – to a real acid test. The experts exposed membranes made of Permeaflon® again and again to AdBlue® for several weeks in a so-called swash test – and they were delighted with the results: From the beginning to the end of the test, the substance dripped off without residue and crystals did not penetrate the robust pore structure. This successful test therefore proved that Permeaflon® is the ideal material for the breathable sealing membranes.

However, Berghof Fluoroplastics stands not only for unique alliances of material properties but also for unique alliances with its customers. The AdBlue® tank caps are also a very good example of this.

Because the sealing technology specialist produces these caps in very large quantities (several millions per year). The obvious question is: How can they be manufactured smoothly and economically? A good thing that the experts at Berghof have always understood the cooperation with their customers as a real partnership.

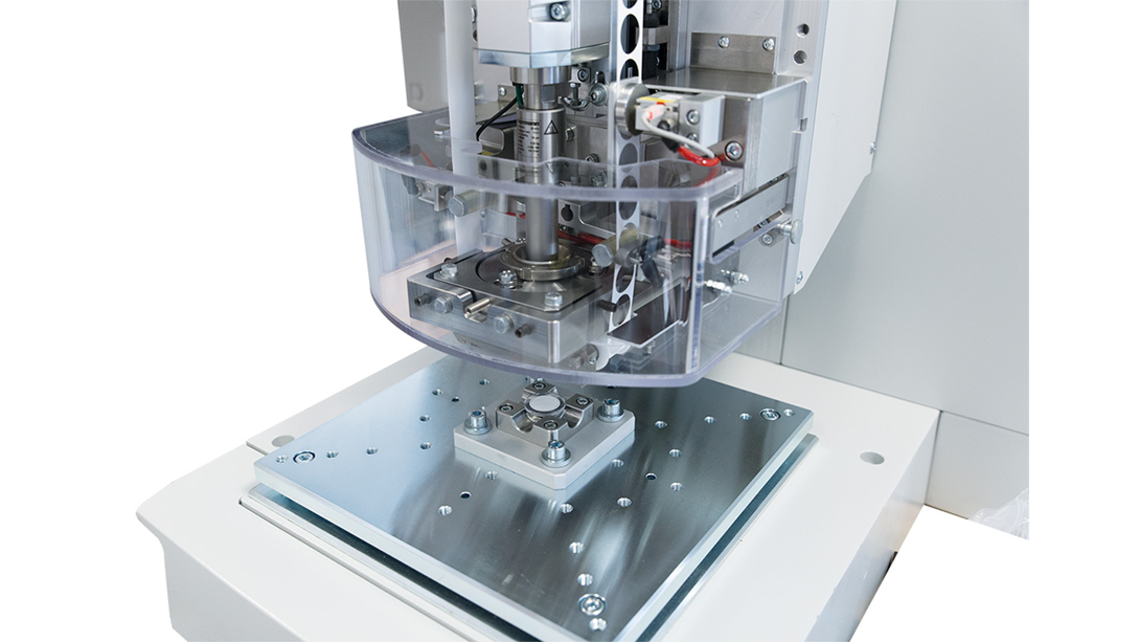

The experts at Berghof Fluoroplastics have brought their customers together with their partner Herrmann Ultraschalltechnik for example. In close cooperation, a production process has emerged based on an ultrasonic welding machine developed by Herrmann which is simpler and more efficient, reduces process steps and saves on assembly auxiliaries.

Step 1: The machine punches the membrane contour out of a material band. Step 2: The so-called sonotrode, a special ultrasonic sealing tool with vacuum suction, transports the punched Permeaflon® membrane to the plastic part. Step 3: The machine joins the membrane and plastic part by ultrasonic welding. Finished!

This smart system has several advantages for the customer: He now works with a less expensive (because not pre-fabricated) membrane material band which Berghof supplies ready for processing. The new process also saves material and time (cycle time: less than two seconds per welding cycle). The previously necessary optical quality check is also superfluous because the system itself checks reliably by a vacuum query whether the membrane is punched and positioned correctly.

“Only” a tank cap? The cap of the AdBlue® auxiliary tank may look unremarkable but technically it has a whole lot to offer.